Meat packaging pads to absorb moisture and delay oxidation

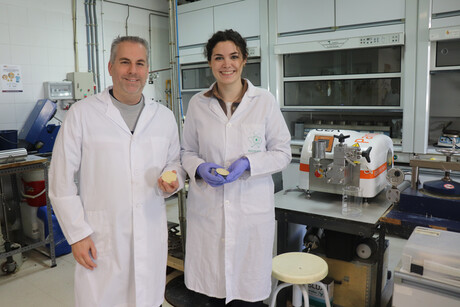

Pads incorporated into fresh meat packaging to absorb moisture and prevent food spoilage are generally composed of plastic polymers derived from petroleum by-products. In a world moving towards avoiding plastic and limiting the environmental impact, the Biopren research group from the University of Cordoba’s Chemical Engineering area has developed natural-waste padding that absorbs moisture, like conventional pads do, but also delays meat oxidation. While this is still in the concept development phase, it has potential as a circular economy solution.

Similar in shape to makeup-removing pads, the meat packaging pads — called aerogels, are composed of three basic elements. The base is made of chitosan, a polymer derived from crustacean shells. Although it is a natural polymer, the material has some functional disadvantages when compared with plastic polymers, such as an irregular structure. It is also weaker and more soluble in water. To combat this, the team added two other elements: nanocellulose from laurel pruning — a widely grown aromatic and medicinal plant crop in the Mediterranean area — and bay leaf essential oil, which help make the pad stiffer and more durable as well as delay oxidation.

Esther Rincón, a member of the research group, said the use of the three elements allows the meat to remain fresh after 10 days of refrigerated storage.

This study, published in the Polymers journal, is a proof of concept.

Further study is required to determine the safety of the pads and whether any of their components can seep into the meat or cause allergic reactions.

Whey to go up: unlocking further potential for cheese by-product

A new mixed-method study explored four models that could provide potential for the Australian...

New farmer incentives to reduce on-farm emissions

Fonterra has announced new funding for farmers to reduce their on-farm emissions.

Food ingredients business installs electric boiler to reduce emissions

Shifting from gas towards electricity from renewables, Arla Foods Ingredients has installed an...