Efficient and reliable disinfection process solutions for food & beverage manufacturing

When manufacturing food and beverage products, it is crucial to exclude contamination. We are, therefore, aware that disinfection processes play an important role here. But how do you dose the disinfectant correctly, ensuring the disinfection process runs efficiently and reliably? And how do you monitor and document the process in view of increasingly strict hygiene regulations?

Safety is the top priority

Sterile conditions are paramount to comply with strict hygiene standards, ensuring safety and quality of products. Even secondary media must be available in the purest form possible under strictly controlled conditions. Nonetheless, it is also important in the food & beverage industry to manufacture products quickly and efficiently. To provide reliable disinfection, a specific, individual level of disinfection must be achieved constantly.

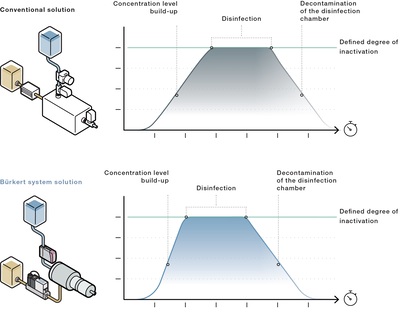

Conventional vs System Solutions

In conventional disinfection units, a simple peristaltic pump doses hydrogen peroxide (H2O2). Speeds and dosing quantities are fixed and cannot be readjusted. Further, there is no way to effectively monitor the disinfection process and to quickly identify errors.

Errors caused by incorrect dosing, a defective pump or a faulty concentration sensor can lead to the required degree of inactivation not being achieved. Troubleshooting is time intensive and complex. Moreover, the disinfection process has to be repeated. And this obviously costs time and money.

The Bürkert system solution for reliable and efficient disinfection processes is based on the generation of a cold aerosol. It essentially consists of a liquid flow controller (LFC), a mass flow controller (MFC) and a high-precision stainless steel mixing nozzle for hygienic applications. The disinfection process can be controlled and monitored via the LFC and the MFC. Hydrogen peroxide and air are optimally mixed to form a fine aerosol, thereby ensuring reliable and uniform inactivation in the disinfection chamber. This means you can be sure that the desired degree of inactivation is achieved.

In contrast to the inflexible peristaltic pump, the compact Bürkert solution allows more aerosol to be dosed into the chamber in the same period of time. As a result, the time it takes to reach the degree of inactivation is reduced. This speeds up the disinfection process. A conventional solution would require a larger plant that is much more expensive to operate.

The advantages of the Bürkert system solution

The Bürkert system solution speeds up the first phase of the disinfection process and can reduce the time required for the whole process by up to 20%. The compact Bürkert solution allows more aerosol to be dosed into the chamber in the same period of time. As a result, the time it takes to reach the degree of inactivation is reduced. A conventional solution would require a much larger heating unit to achieve comparable time savings, but this would increase the costs of ownership and make the overall system more expensive and bigger.

We are confident that our Bürkert system solution can also meet your individual requirements in terms of reliability, efficiency, flexibility and engineering. By the way, Bürkert offers comprehensive support — from development to series production.

Tried and tested with the food & beverage industry across the globe, our hygienic solutions are a proven success amongst our customers.

Smart AI solutions shaping Australia's food future

With Australia approaching a federal election in the coming months, the government is stepping up...

Detection and Quantification of Lactose in Dairy Products

The Neogen Megazyme K-LOLAC test kit is a widely used enzymatic assay for the quantitative...

Complete processing lines for savoury snacks: challenges and opportunities

The global savoury snack market faces several challenges and opportunities.