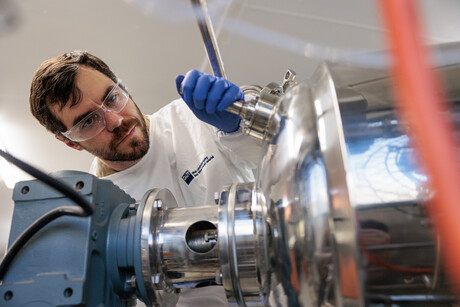

Creating future foods using precision fermentation at Mackay pilot plant

A $3.9 million project will complete the transformation of the QUT Mackay Renewable Biocommodities Pilot Plant (MRBPP) into a state-of-the-art, food-grade-compliant facility which will be designed to enhance Australia’s ability to produce novel food ingredients.

Professor Ian O’Hara, who led the development of the MRBPP more than a decade ago, said the co-investment between QUT and Australia’s Food and Beverage Accelerator (FaBA) would expand the facility’s capability and allow companies to fast-track product development in the food and beverage sector.

“This project is part of an overall $16 million upgrade to the facility to be completed this year which will transform the pilot plant into Australia’s leading physical containment level 2 (PC2) large-scale, food-grade research translation facility,” O’Hara said.

“This will enable the production of novel food and beverage ingredients via precision fermentation and boost product development by providing a unique capability to undertake early-stage scale-up, reducing cost and timeframes for getting new products to market.

“Precision fermentation allows us to manufacture new high-value food ingredients like proteins that can boost our bioeconomy in Australia and provide new domestic and export opportunities for our agricultural and food and beverage industries.”

The QUT research team involved in the project includes Professor O’Hara, Professor Jolieke van der Pols, Associate Professor Mark Harrison and Dr Jo Blinco.

Precision fermentation is a technology that allows us to convert sugars into a range of other food ingredients and products in brewery-style fermentation tanks.

Unlike traditional fermentation, which is used to make products such as beer and yoghurt, precision fermentation tunes the microorganisms to produce specific enzymes, fats or proteins and allows the team to do this at large scale.

“The advantages of precision fermentation are that it can lead to new food products and ingredients that are not possible to produce through traditional methods, providing sustainability benefits and increasing consumer choice,” O’Hara said.

Dr Chris Downs, FaBA Director, said the Accelerator had invested in the pilot plant to enable industry to scale and ensure onshore production of innovative ingredients.

“The pilot plant has the potential to help cement Australia’s position as a leader in the development of ingredients from precision fermentation,” Downs said.

FaBA is hosted by The University of Queensland, in collaboration with partners QUT, the University of Southern Queensland and UniQuest. It is supported by the Australian Government’s Department of Education through the Trailblazer Universities Program.

In addition to the investments by QUT and FaBA, the Mackay Pilot Plant upgrade is being supported by the Australian and Queensland Governments through the Regional Recovery Partnerships Program and the Queensland Government Department of State Development and Infrastructure through the Industry Partnership Program.

Australia's southern bluefin tuna achieves sustainable certification

Claimed as a world's first, the Australian Southern Bluefin Tuna Industry Association has had...

New Zealand wine industry’s report shows commitment to sustainability

The 2025 New Zealand Winegrowers Sustainability Report highlights the ongoing efforts by NZ grape...

Futureproofing Aussie wines with mildew-resistant grapevines

CSIRO and Treasury Wine Estates have partnered on a project in South Australia to help protect...