Oxygen pick-up in beer filling

Brewers are all too aware of the fact that beer reacts sensitively to oxygen, and off-flavours can result if there’s too much oxygen pick-up. Craft beers made using the rediscovered cold or dry hopping technique are susceptible to altered taste as a result of oxygen pick-up. Standard light beers are also especially sensitive to oxygen; on the other hand, dark beers often display considerable flavour tolerance to an oxygen content of above and beyond 0.1 mg/L.

Oxygen pick-up in beer production starts with the crushing of the malt and continues even after the beer has left the brewery, as oxygen penetrates seals on crown corks, for instance, up to the point where the beer is drunk. Beer ingredients react so fast with oxygen that dissolved oxygen measurements have to be taken immediately after the respective processes of tank filling, filtration or bottling, for example. An oxidised beer with its typical changes in taste often contains barely measurable amounts of oxygen, yet the negative impact on quality is substantial.

The use of additives such as bisulfite or ascorbic acid as oxygen scavengers is common in countries other than Germany, especially when filling beer into PET bottles. This is because these containers, plus the PE or PP caps most commonly used to seal them, allow relevant amounts of oxygen to migrate very quickly. Using ascorbic acid as an antioxidant in beer is a two-edged sword, however. Oxidation processes — not just in beer but also in other beverages such as soft drinks and juice — are complex procedures with many intermediate stages and thus much more than simply the transfer of oxygen to a specific receptor molecule. Are the polyphenols in the malt or hops beneficial antioxidants or damaging haze formers? This is a different story altogether that scientists continue to research.

In order to rise to this challenge, breweries have developed a number of approaches to quality assurance: from the use of malts low in polyphenols to polyphenol-rich whole cone hopping or from strategies for preservation or precipitation of the polyphenols to those aimed at polyphenol reduction using PVPP.

Avoiding or reducing oxygen pick-up for flavour stability

The expert community agrees that avoiding or reducing oxygen pick-up is the most important step in achieving the longest possible flavour stability. To this end, tanks are pressurised with inert gas, for instance, and often cleaned in the presence of this gas to prevent any loss of it. If the inert gas is CO2, only acidic cleaning is possible on retention of this gas. If N2 is used, the amount of dissolved N2 in the beer must be observed to achieve an undisrupted filling performance and not generate any untypical foam structures for the consumer. Alternatives such as argon would be prohibitively expensive.

As a general rule, tank pressures should be selected so that they are as low as possible to match the partial CO2 pressure of the beer and in order that pumps can be used for any necessary pressure increases. During filtration the use of deaerated water is strongly recommended. An oxygen content of below 0.2 mg/L is to be aimed for here — also for purging water during flash pasteurisation, for example — as non-deaerated water contains about 10 mg/L.

Measuring the amount of oxygen when monitoring purging processes with mixing phase separation reveals deficiencies much earlier than measuring the original gravity, for instance. Today’s requirements and opportunities are such that it even seems prudent to abandon the mg/L (~ ppm) unit of measurement used to date for oxygen pick-up and instead switch to the more convenient unit of µg/L (~ ppb).1 Prior to filling, beer not infrequently contains 5 µg/L of oxygen or lower: in other words, less than 0.005 mg/L. Whereas a few years ago filling systems that achieved total oxygen pick-up levels of 150 µg/L were common, nowadays as little as 20 µg/L are possible with the right technology.

Determination of the total oxygen content

The total oxygen content, often referred to as the TPO or total packaged oxygen, includes both the oxygen dissolved in the beer and that found in the head space of the closed container. The method for ascertaining the ‘air in the head space’ by transferring this head space gas into a burette filled with caustic to adsorb the CO2 is still used today for reasons of simplicity. However, the gas composition in the head space does not only comprise CO2 and air with the usual percentage of oxygen. This therefore renders the ‘air in the head space’ not entirely suitable for the determination of the TPO. Measuring devices are now available for precise stipulation of the total oxygen content that measure both the head space oxygen and the oxygen dissolved in the beverage more or less automatically. Together with temperature and complex pressure measurements, here the head space volume, CO2 content and even other dissolved gases are computed entirely automatically.

Almost 40 years ago, master brewers Uhlig and Vilachá from the Polar Brewery in Caracas, Venezuela, developed a formula that, using an oxygen measuring device for dissolved oxygen and by determining the temperature and head space and filling volume, was also able to establish the TPO with high precision. For this purpose, the containers are brought into a state of gas equilibrium by agitation. This method has the advantage that all process steps in beer production and filling can be monitored by a single mobile device; with it, even gas-in-gas measurements are now possible, with only an additional piercing device with an inert gas supply needed for measurements taken from bottles or cans. The dissolved oxygen of a beverage in a state of gas equilibrium in a bottle or can must then be multiplied by a calculated factor to obtain the TPO. This factor lies between two and three for normal containers and filling temperatures. Modern filling machines achieve measurement values for dissolved oxygen that in agitated containers even lie below those taken upstream of the filler. In comparison, measurements in unagitated containers yield information on the efficiency of the essential foaming prior to closure or on the construction and configuration of the undercover gasser on a can seamer.

This comparison reveals that on modern filling systems the filling process as such is only accountable for 10 to 20% of the total oxygen content in a filled and sealed container. Oxygen pick-up during filling is always to be seen in relation to the inert gas consumption required for this process. Whereas in the past such low oxygen pick-up was impossible even with high consumption levels — or was possibly considered unnecessary — considerable improvements have since been made.

Depending on the required or selected filling method, N2 can now also be used — today, this can be produced at a reasonable price in-house by molecular sieves.

Case study: technologies for good beer quality

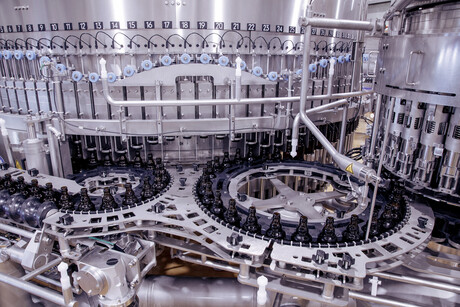

In beer production, breweries can obtain good quality with a low oxygen content with the help of the latest technology. First and foremost, this makes the use of additives such as bisulfite or ascorbic acid as oxygen scavengers superfluous. This is exactly the point KHS has addressed with the development of its modular Innofill Glass DRS ECO filling system.

There are currently 23 sites across the world using the filling technology and one such site is the OeTTINGER Brewery in Mönchengladbach, Germany.

The technology has been engineered to let less oxygen into the beer — and in doing so consumes not more but less CO2 than its predecessor. During bottle filling a new hollow probe filler enables reduced CO2 consumption on the one hand and even lower oxygen pick-up on the other.

The container is first evacuated through the vacuum channel and then purged with CO2 gas. A KHS-patented purging process is used to this end. The container is then pressurised to filling pressure with the inert gas as usual. This makes a low total oxygen pick-up of 20 ppb possible at a CO2 consumption of 160 g/hL. Further reducing the CO2 consumption to 110 g/hL, for example — half of what was usual to date — also facilitates a low oxygen pick-up of 40 ppb. The required total oxygen pick-up can therefore be selected as needed, meaning that a range of automatic product type conversions can be set with maximum CO2 savings for an especially oxygen-sensitive cold-hopped beer, a dark beer insensitive to oxygen or even for totally different filling products such as soft drinks.

The lower the consumption of carbon dioxide for the filled bottle, the more efficient the production process — and the lower the oxygen pick-up, the better the product quality. Also, the KHS digital and automated systems synchronise the filling processes and thus further boost efficiency.

1. 1 ppb = parts per billion; 1 ppb is the equivalent of 1 µg per kilogram, for example.

In-house ginger processing for beverage maker

A ginger beer manufacturer reduces its supply risk by investing in pack-house technology to...

Tailor-made solutions for sliced meat on show at IFFA

At this year's IFFA in Frankfurt, the MULTIVAC Group will be showing its latest line...

Five ways emerging tech can help food and beverage manufacturers

As food manufacturers embrace new innovations, they must also navigate the complex landscape of...