Use-by dates could be past their use-by date

Tuesday, 21 March, 2023

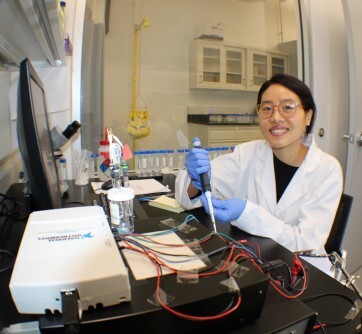

Forget that expiration date on your salmon or yoghurt. A graduate student at Southern Methodist University (SMU) has developed a miniature pH sensor that can tell when food has spoiled in real time.

Only 2 mm in length and 10 mm wide, the compact sensor can be incorporated into current food packaging methods, such as plastic wrapping. Typically, bulkier meters are used to measure pH levels, which are unsuitable for incorporating into food packaging.

Khengdauliu Chawang, PhD student at SMU’s Lyle School of Engineering and lead creator of the device, said the sensors work like the small wireless radio-frequency identification devices inside luggage tags at airports. “Every time a food package with our device passes a checkpoint, such as shipping logistics centres, harbours, gates or supermarkets’ entrances, they could get scanned and the data could be sent back to a server tracking their pH levels.

“Such configuration would allow continuous pH monitoring and accurately detect freshness limits along the entire journey — from farms to consumers’ houses,” Chawang said.

The Institute of Electrical and Electronics Engineer’s (IEEE) Big Ideas competition at the 2022 IEEE Sensors Conference awarded Chawang with the Best Women-owned Business Pitch for her invention, which she built with the support of J.-C. Chiao.

Chiao, who joined the SMU faculty in 2018, is recognised for his research in using electromagnetic waves in medical applications including closed-loop pain management systems and gastric motility management.

How the sensor works

Food freshness level directly correlates to pH levels, which is measured by the concentration of hydrogen ions found in a substance or solution.

Because hydrogen ions are electrically charged molecules, the electrodes within Chawang’s pH sensor can detect the electrical charge generated by the concentration of hydrogen ions inside food, converting the level to pH values using what is known as the Nernst equation.

According to Chawang, the pH sensor has been successfully tested on food items such as fish, fruits, milk and honey. More testing is underway.

The pH sensor is made from a small amount of biocompatible materials and uses printing technologies on flexible films. It doesn't require expensive equipment or semiconductor cleanroom environment to produce, which can help to keep the costs low for the disposable sensor.

Chiao and Chawang are now testing whether the device can also be used to ensure reliable fermentation for cheese and wine. It could also have possible medical applications in detecting early warning signs of sepsis or wound infection when used on the skin.

Adapting the Australasian cold chain for a sustainable future

With challenges rapidly changing the landscape of cold storage operations, businesses must adapt...

Four trends shaping warehouse automation and intralogistics in 2025

Four key trends expected to shape the warehouse automation and intralogistics industry in...

Unlocking AI: strategic moves to revolutionise the food sector

As the AI transformation gathers pace, we can expect AI tools to become established in the food...