Four digital trends shaping the beverage industry

Wednesday, 03 February, 2021

The beverage industry has been steadily implementing and capitalising on the benefits of digitalisation — using tools such as digital twins, blockchain solutions, artificial intelligence and robotic technology.

A Siemens study on the food and beverage industry predicts digitalisation investments will reach $567 billion for the next five years.

Digital twin

The concept of digital twins is a tool particularly well suited to the beverage industry. By digitally simulating a beverage machine and integrating its data into software tools, functions can be tested in real time before the machine is built. The digital twin also helps ongoing machine operation by avoiding downtime. Moreover, the process data can be shared with others — even beyond one’s company. Before maintenance, the manufacturer can simulate real production conditions and adjust the maintenance intervals to the actual machine load. However, the company providing the data always remains in control of the use of its data.

For example, Krones uses digital twin programs to simulate and calculate the positioning performance of three-armed robots in the packaging process. This allows for status diagnostics improvements to be conducted during ongoing operation, even without access to the physical device.

Blockchain technology

Connection forms the basic principle behind another digital technology that could help evolve the beverage industry. Blockchain is a software system that combines data in unchangeable lists via a forgery-proof method (distributed ledger) and can comprehend the entire supply chain of products. Blockchain solutions are already commonly used today, particularly for verifying product authenticity. According to industry experts, this technology is predicted to generate savings of $31 billion by 2024 — all by improving supply chain traceability, reducing the time required and simplifying the recall process.

For example, blockchain technology can be useful for tracking raw malt in the beer industry. Belgian beer group AB InBev recently reported that, from 2021, the company could use a QR code to discover the origin of the malting barley and its manufacturing process. It was initially intended to connect grain farmers in the north of France with the malthouses in Antwerp, Belgium, and the Stella Artois brewery in Leuven, Belgium. AB InBev expects the technology will benefit not only consumers but also the agricultural industry and its environmental footprint.

In another example, blockchain solutions will also soon provide comprehensive product information for sake, the traditional Japanese rice wine. Distributed ledger technology for the sake blockchain will gather information regarding the ingredients, brewing process and control measures into the supply chain. The consultants for this project expect that this will lead to a higher price for the product.

Artificial intelligence

Artificial intelligence (AI) could also play a role in the continued development of digital solutions for the beverage industry. A cross-industry study by the Fraunhofer Institute for Industrial Engineering IAO of more than 309 companies shows that 75% of the surveyed companies are currently engaged with AI. A total of 16% already use the technology.

For example, Swedish whisky distillery Mackmyra uses AI to automate the challenging aspect of recipe generation. The distillery combines machine learning models and calculation algorithms via a data cloud to calculate new recipe component combinations. The company hopes to offer consumers innovative whisky flavours. The first whisky based on these calculations has already been created. It was awarded ‘Gold’ by the American Distilling Institute.

In another example, AI is used to research methods for reducing food waste by up to 90%. Two supply chain points are crucial here: minimising overproduction and avoiding wastage. This allows for consumer demands to be more accurately predicted and for production infrastructure to react quickly to both fluctuating demand and differences in the quality of raw materials.

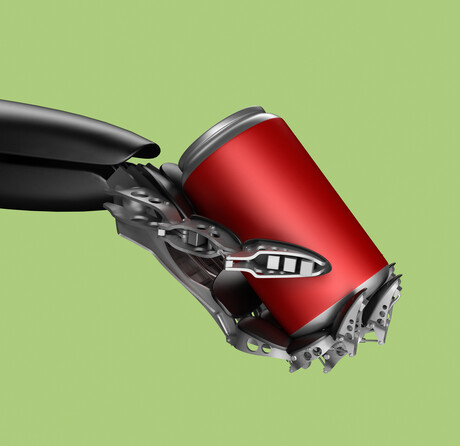

Robots — cleaning the plant

Robotics, digital twins and artificial intelligence have been combined in intelligent cleaning robotics for interiors and exteriors. A research team from the Fraunhofer Institute for Process Engineering and Packaging IVV in Dresden has developed two types of modular cleaning robots: one drives through the production plant via conveyor belt and cleans it from the inside, while the second cleans the floors, ceilings and walls of rooms, as well as production machine exteriors. An extendable robotic arm with a jet cleaner also reaches the higher-up areas.

The intelligent factory is within reach

Networked, adaptive and real-time production simulations are not far off. Moreover, the benefits are also quantifiable. The one thing that should not be forgotten is that people need to be able to interpret and handle the data. Data scientists are acting as the domain experts to develop the data usage in the process.

Many of these trends will be further discussed at the industry event drinktec 2021, which will run from 4–8 October in Munich.

Unlocking AI: strategic moves to revolutionise the food sector

As the AI transformation gathers pace, we can expect AI tools to become established in the food...

The development of food GMPs

Good manufacturing practices (GMPs) in the food industry are in place to ensure that the products...

Improving traceability with a warehouse management system

When it comes to supply chain management, advanced technologies are playing a role in optimising...