What processes do NASA and the food & beverage industry have in common?

Is it state-of-art technology? Perhaps the need for continuous improvement? Or could it be the search for foreign organisms (not a good thing in the F&B industry)? Let's take a more in-depth look.

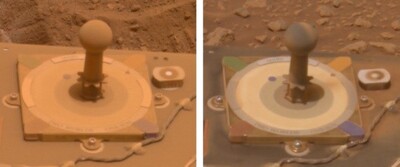

To send images with the necessary resolution to accurately understand what’s happening on Mars’ surface, our fellow NASA engineers must calibrate the Rover Camera periodically to compensate for soiling and radiation exposure.

By definition, a calibration is simply a comparison of a measurement value to a known standard. With the Mars Rover, a small reference is used to calibrate and adjust parameters such as colour and brightness when necessary to ensure image resolution and accuracy.

This accuracy and reliability are essential to prevent NASA from discovering that the sympathetic alien captured in the photo was, in the end, a rock.

After calibration, the observed deviation is a crucial resource for identifying faulty components, including those worn down by time. This information allows them to correct and predict failures more than 200 million kilometres away from home. Cool, right?

What exactly does this have to do with my process instrumentation?

Like this exploratory space robot, process instrumentation is exposed to harsh process conditions: temperature variations, abrasion, mechanical stress and chemical attack, resulting in structural changes and fatigue that can lead to measurement errors over time.

Regular calibration is necessary to identify anomalies and measurement inconsistencies that might impact your production.

In the food and beverage industry, there are four main aspects where calibration could significantly impact your processes: cost savings, efficiency, quality and safety. Let’s take a more in-depth look into them.

Cost savings

Very often, we neglect the impact of measurement uncertainties, primarily when they are small. But have you ever considered how much a 0.1% improved accuracy in your flow measurement can save you after a year of production?

Imagine that you produce 1,000,000 (one million) litres of beer per year to make things simple. An error of 0.1 % on just one flowmeter can be accountable for 1000 litres/year sent to waste due to measurement uncertainties.

Considering these uncertainties are expanded (ie, accumulated) throughout your whole production chain, the losses can go up to the hundreds of thousands of dollars in product waste, quality issues and waste treatment!

Energy efficiency

Another excellent example of how proper calibration can reduce costs and optimise resources is in processes where heat is necessary, such as pasteurisation.

A temperature transmitter indicating 140°C while the actual temperature is 142°C means an additional steam consumption.

Considering a 5000 hours/year operation time and a 30 kg/h of steam necessary to increase the process by 2°C, the process will spend an extra 150 tons of steam due to a non-calibrated device.

PS: The extra amount of steam generated represents approximately 20 kg of CO2 emission per year (literally, not cool).

Temperature is the most used variable within the F&B industry, with some sites having hundreds of measuring points. Can you imagine the overall waste of energy if you consider the deviation of all measuring points in your plant?

Plant safety

In an industrial plant, applications such as temperature and flow in cooling systems, overfill protection systems, gas line and filter pressure are considered safety-critical points.

As previously mentioned, the calibration data helps to identify measurement errors and failure-prone components, backing the instrumentation diagnostics to mitigate and reduce failure risks.

Quality and regulatory compliance

Within the F&B industry, critical control point instruments are monitored and calibrated regularly to comply with hazardous plans, internal and external standards.

In this aspect, the proper calibration ensures a high consistency production due to low measurement errors and provides the appropriate evidence to ensure the process runs under safety conditions.

What are the essential requirements for proper calibration?

To have a reliable calibration, you have to ensure:

- Proper calibration equipment — The standards used for your device’s calibration must have a smaller measurement uncertainty and be based on an equal or superior method of your process instrumentation.

- Full Traceability — To ensure your calibration execution with up-to-date instruments, always ask your supplier for the primary standard documentation and use of proper methods and recognised institutes for its calibration.

- Standard Operating Procedures (SOP) — The calibration procedure can influence the so-called expanded uncertainty of the calibration. Meaning that different companies can perform calibrations in different ways, using other resources and supplying non-standardised documentation.

Whether on Earth or Mars, calibration is necessary to ensure quality. The selection of a reliable partner capable of fulfilling all the technical requirements for a state-of-art execution is critical to secure your process performance, reduce costs, and increase process safety.

Endress+Hauser offers a full range of calibration services in both our facilities and on-site.

You can find out more at: https://www.au.endress.com/en/instrumentation-services/calibration-services

Reference:

https://mars.nasa.gov/mer/mission/instruments/calibration-targets/

Mastering plant-based meat analogues: innovative extrusion with alternative proteins

Food innovators are searching for alternative protein sources to create meat analogues for a...

Anton Paar’s “Field Guide to Plant-Based Food Analysis”

Understanding the complexities of plant-based ingredients and products is paramount.

Accelerating research and development of plant-based meat

The rough estimation of global meat consumption is that it accounts for almost 30% of the total...