The ubiquitous can

By Emeritus Professor Harry Lovell OAM, FAIP

Tuesday, 31 March, 2015

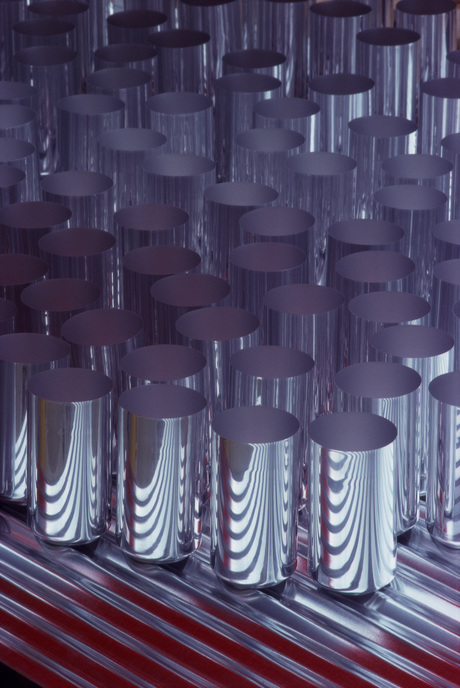

One of the most intriguing features in the history of packaging has been the use of metal, the most striking application being that of the food can. At a time when plastic materials have been used in every conceivable format, the can has kept its place as a reliable and trustworthy pack and retained the confidence of consumers.

The history of canmaking and canning processes has been well documented and progress has been visible to consumers: two-piece cans with easy-open ends, shaped cans and new decoration techniques. Research and development, however, is not only concerned with improving marketability but also with improvements to manufacturing operations.

In the case of the hermetically sealed can, the process of drawing the metal body was a significant step forward. The double seam (invented by Max Ams in 1896) should also receive attention. Over many years the assessment of the double seam has involved some mechanical operations to measure and assess seam quality.

Inevitably, the ‘tearing down of seams’ has the potential to cause some distortion to the metal. While this has been carried out skillfully and produced results which give confidence that a satisfactory hermetic seam has been formed, it is still a destructive process. However, the process of ‘seam teardown’ can now be replaced by a static examination using X-rays. Developed by CMC KUHNKE, the SEAMSCAN XTS X-RAY tightness scanner provides a ‘virtual teardown’ of the seam to give detailed measurement for the seam components - even including wrinkle amplitude. The expansion of new techniques of quality assessment has provided new insights into measuring performance requirements.

While there has been a significant improvement in facilitating seam assessment and other attributes, there have been concomitant developments in the formation of the double seam with attention being directed to the profiles of the seaming rollers and the precision with which they carry out their function. This has facilitated an increase in can manufacturing speeds (ie, 450 cpm) with the consequence that routine maintenance requirements have become more demanding.

In 2012, Swiss company Ferrum announced a new development in machine monitoring. A small device added to its can seamers allows access to the can seamer at any time, enabling the company to advise the customer with respect to performance etc, and draw attention to service requirements. Currently the new system - ferruTell - can provide up to 60 machine parameters.

The canning industry has a proud record extending over 100 years. Consumers can have confidence in the canning industry secure in the knowledge of its safety record.

Lifting the lid on the benefits of sodium reduction legislation

A study has found that mandated sodium reductions for processed food in South Africa since 2013...

Getting the right texture: toolkit to help create more appealing food

The FaBA Texture Library Toolkit has been developed to help manufacturers improve the texture of...

What's new on the shelf: new food products for Easter

From spicy snacks and creative Easter treats to icy and elevated flavours for winter, here's...