Next-gen nuggets using chunky cultured chicken

International researchers have produced bite-sized chunks of chicken with the texture of whole meat in the lab using a bioreactor. While further research is needed to improve the taste and texture of the cultured meat, the technology could one day provide an alternative to animal meat in many applications, such as cultured chicken nuggets.

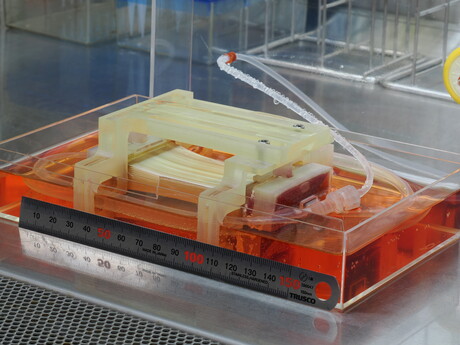

The team of researchers used a Hollow Fibre Bioreactor (HFB), which mimics a circulatory system to deliver nutrients and oxygen to artificial tissue, and a robot-assisted assembly system to produce bite-sized pieces of whole-cut chicken meat of more than 10 grams using chicken fibroblast cells, which make up connective tissue.

“Our study presents a scalable, top-down strategy for producing whole-cut cultured meat using a perfusable hollow fibre bioreactor,” said senior author Shoji Takeuchi of the University of Tokyo. “This system enables cell distribution, alignment, contractility and improved food-related properties. It offers a practical alternative to vascular-based methods and may impact not only food production but also regenerative medicine, drug testing, and biohybrid robotics.”

A significant obstacle to the reconstruction of large-scale tissues is the creation of well-distributed vascular networks because diffusion alone cannot sustain cells across considerable distances. The thickness of tissues without an integrated circulatory system has generally been limited to less than 1 mm, making it challenging to produce centimetre-scale or larger tissues with densely packed cells.

“We're using semipermeable hollow fibres, which mimic blood vessels in their ability to deliver nutrients to the tissues,” Takeuchi said. “These fibres are already commonly used in household water filters and dialysis machines for patients with kidney disease. It's exciting to discover that these tiny fibres can also effectively help create artificial tissues and, possibly, whole organs in the future.”

The authors demonstrated the biofabrication of centimetre-scale chicken skeletal muscle tissues using a Hollow Fibre Bioreactor consisting of an array of 50 hollow fibres. In addition, they implemented a robot-assisted assembly system for the fabrication of a 1125-fibre HFB and produced whole-cut chicken meat weighing more than 10 g using chicken fibroblast cells, which make up connective tissue.

“We overcame the challenge of achieving perfusion across thick tissues by arranging hollow fibres with microscale precision,” Takeuchi said. “Remaining challenges include improving oxygen delivery in larger tissues, automating fibre removal and transitioning to food-safe materials. Solutions may include use of artificial oxygen carriers to mimic red blood cells, bundle-removal mechanisms that efficiently remove fibres in a single operation, and edible or recyclable hollow fibres.”

The authors have patent applications related to this work and the findings have been published in the Cell Press journal Trends in Biotechnology.

Lifting the lid on the benefits of sodium reduction legislation

A study has found that mandated sodium reductions for processed food in South Africa since 2013...

Getting the right texture: toolkit to help create more appealing food

The FaBA Texture Library Toolkit has been developed to help manufacturers improve the texture of...

What's new on the shelf: new food products for Easter

From spicy snacks and creative Easter treats to icy and elevated flavours for winter, here's...