Rockwell Automation technologies form part of smart manufacturing lab in Qld

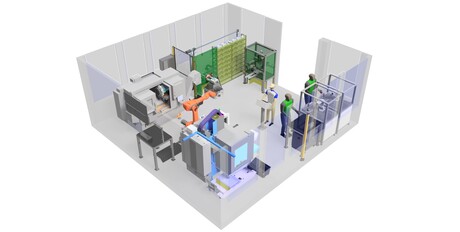

A new $3m advanced manufacturing lab is being built by Applied Robotics for TAFE Queensland, funded through the Queensland Government’s $100 million Equipping TAFE for our Future program.

The new lab, scheduled for installation in February 2025, will feature several key Rockwell Automation technologies, cleverly designed to train the next generation of Australian engineers, manufacturers and innovators.

“We’ve had a long partnership with Rockwell, extending more than 30 years, so when we won the project to deliver this smart manufacturing lab, we knew Rockwell had the expertise and technologies to meet our needs,” said Isaac Roach, chief operating officer at Applied Robotics, which is a Silver OEM partner in the Rockwell Automation PartnerNetwork.

“Not many suppliers have all the technologies under one roof, but with Rockwell, we could get IoT [Internet of Things], MES [manufacturing execution systems], logistics technologies, PLCs [programmable logic controllers], digital twin visualisation and AMRs [autonomous mobile robots] all from the one supplier,” he added.

“Applied Robotics is an OEM solutions provider that caters to the more complex end of automation, and Rockwell is one of our preferred suppliers due to its quality product, technical expertise and customer service.”

The new lab, to be installed at TAFE Queensland’s Ipswich campus, will focus on training students in areas such as robotics, CNC (computer numerical control) machining, machine vision and learning, and automated logistics and storage.

“A key outcome set out by the TAFE was that we needed to be able to train the trainers, so they are well-equipped to teach students in the new lab. Rockwell was instrumental in achieving this, particularly with its Plex software running the entire system with control down to the device level,” Roach said.

Plex is a Software as a Service (SaaS) smart manufacturing platform that connects people, systems, machines and supply chains. It is a digital system of record that automates business processes, tracks data from the shop floor to the top floor, and delivers analytics to improve visibility, quality and control.

“It’s vital to nurture the next generation of manufacturing talent, and advanced labs like this will help train Australia’s innovators and entrepreneurs of the future,” said Anthony Wong, regional director, South Pacific, Rockwell Automation.

Food of the future: Anuga presents food trends for 2025

Anuga, together with Innova Market Insights, presents future food trends and focal themes for its...

Heat and Control announces acquisition of Tek-Dry Systems and Hunt Heat Exchangers

Heat and Control has announced the acquisition of two UK-based providers of thermal processing...

Global dairy markets shift under tariff pressure

Major dairy exporters face diverse market and production conditions with geopolitical tensions,...