Effluent monitoring

The increased pressure from government to decrease biochemical oxygen demand (BOD) effluent loads and to reduce the risk of spikes in pH in effluent has been quite evident. Ensuring your plant has an accurate and available pH measurement is more important than ever.

Ensuring the accuracy and stability of a pH point has long been a challenge of the industry and something which takes effort and resources to achieve.

Additionally, traditional BOD5 measurements are inherently slow and costly, and never alert you to real-time events that can then be managed.

The solution

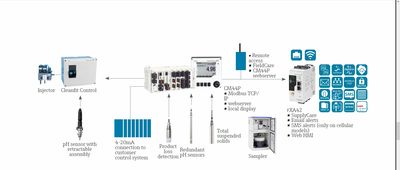

Endress+Hauser has developed an in-line pH system capable of self-cleaning to ensure continual reliable operation. The system can operate with pH alone or with the addition of CODeq (for correlation to BOD), total suspended solids and product loss detection sensors depending on the nature of the trade waste agreement in place with the local water authority.

Self-cleaning pH

The system comprises the digital Memosens technology pH sensor CPS11D, Liquiline CM44x transmitter, a pneumatically retractable pH assembly CPA875 and the Cleanfit Control CYC25 interface.

In order to provide functional feedback and ensure an accurate and consistent measurement, the pH electrode is retracted from the process, cleaned with water and a cleaning chemical and then automatically reinserted into the process without any manual intervention. This ensures that drift associated with electrode fouling is kept to a minimum for the duration that the pH electrode is kept in service. It also reduces the manual maintenance requirement as well as lengthening the calibration interval further reducing operational costs.

The cleaning interval is triggered either externally via the customer’s PLC, or based on a predetermined time interval through the CM44x transmitter. The cleaning regime is fully programmable using the inbuilt Chemoclean Plus program which allows for any number of rinsing and cleaning cycles as well as inverse measurement (where the sensor is normally located out of the process and only inserted when required). This ensures that the cleaning program is entirely built around each and every individual customer process which results in a better clean.

Traceability

All measurements are recorded within the CM44X transmitter and captured by the Endress+Hauser service team and delivered as a report each month. This historic data can be used for analysis, trending and in the case of federal or provincial audit.

This data can also be uploaded to your W@M Endress+Hauser asset management portal so that it may be stored in one central location.

Identifying high loads

Similarly, by using a fast responding UV sensor at 254nm, a correlation can be determined between the CODeq (Chemical Oxygen Demand Equivalent) measurement and the BOD5 load.

The CAS51D UV sensor has been designed for use in effluent plants. Its robust design has no moving parts which ensure a reliable measurement and with a service interval of every two years, it provides for a low cost of ownership.

The sensor measurement occurs multiple times per minute ensuring that any off spec or high loads are captured immediately and are able to be rectified before discharge to the sewer. The raw measurement can be used directly or in many cases correlated to a BOD5 value via comparison and calibration to laboratory determined values.

The benefit is real time monitoring of the organic load going into and also out of the plant, so that any unplanned high loads are captured before they have a chance to enter the waste water system.

With BOD5 charges at roughly $1.20/kg (dependent on load) and fines up to $15,000, the savings can be recouped after only one or two events have been identified and stopped from discharging into the sewer.

As the data captured is readily available, it is possible to trend spikes in CODeq, daily, weekly and monthly to show trends during these periods. Having access to the time and size of these spikes gives a layer of transparency to the possible processes or activities which are run at these times. This helps you to trend and identify key ways in which to reduce the risk of spikes in effluent loads.

Remote monitoring

Using the Endress+Hauser FXA42 FieldGate, your measuring system communicates via SMS and email to both key stakeholders within your organisation, as well as highly trained Endress+Hauser technicians.

Instant notice of spikes in pH or CODeq in your effluent load allows you to take the necessary action when it counts.

Endress+Hauser factory-trained technicians immediately log remotely into your system to see what is happening within the process and ensure the spikes recorded are being addressed.

When a probe measures outside of tolerance due to probe life or maintenance, Endress+Hauser service department schedules a service visit to rectify the issue and ensure the system is functioning as it should. This way, your monitoring system is always accurate and reliable.

More than meets the eye

Due to the modular design of the CM44x transmitter and the digital Memosens protocol, the system may be further equipped with product loss detection and total suspended solids measurement. For compliance to regulatory authority requirements an Endress+Hauser CSF48 Automatic Sampling System can also be supplied to ensure you have more information and insight into your effluent process.

Benefits

Monitoring and trending your plant’s effluent with pH and BOD ensures:

- Your plant meets all federal and provincial legislation in order to avoid fines

- Availability of historical data of your effluent loads for traceability

- Gain transparency of effluent leaving your facility to identify the processes and activities in your facility which lead to product losses

- Trust in your pH measurements and receive immediate email and SMS notifications for pH spikes in effluent load

- Peace of mind, knowing your effluent loads are under control

Turning sustainability into an advantage in food and beverage

Nearly half of all Australian shoppers are influenced by sustainability when making purchases,...

The 'flour effect' pathway to Scope 3 emission cuts

An Australian Study reveals how a simple ingredient could become a climate solution for food...

Whey to go up: unlocking further potential for cheese by-product

A new mixed-method study explored four models that could provide potential for the Australian...