'EPR on a chip' developed to test olive oil and beer quality

The first sign of spoilage in many food products is the formation of free radicals, which reduce the shelf life and overall quality of the food. The food industry has gone to great lengths to detect these highly reactive molecules, either with chemical methods or via the only direct method, called electron paramagnetic resonance (EPR). But conventional EPR machines use electromagnets, which do not allow battery operation and are expensive to buy and operate.

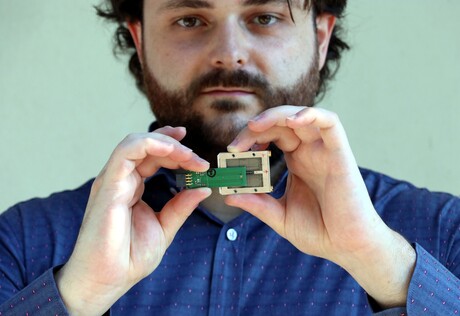

Now researchers at Helmholtz-Zentrum Berlin (HZB) and the University of Stuttgart have developed a portable, small and inexpensive ‘EPR on a chip’ or EPRoC sensor that can detect free radicals even at very low concentrations. The sensor will initially be used in the production of olive oil and beer to ensure the quality of these products.

The development of the EPRoC goes back to an idea by Klaus Lips (HZB) and Jens Anders (University of Stuttgart), which won the HZB Technology Transfer Award in 2019.

“A lot has happened since then, so that we can now plan a spin-off company,” said physicist Michele Segantini (HZB), who is about to complete his PhD in Lips’ department. The new startup company, called SpinMagIC, will now offer a EPR sensor that fits on a small chip.

“We will produce small, portable and affordable EPR devices based on the combination of a microchip and permanent magnets that can be tailored to the customer’s needs,” Segantini said.

In addition to Segantini, the founding team includes electrical engineer Anh Chu, physicist Belal Alnajjar and economist Jakob Fitschen.

“We see a huge potential for applications, initially mainly in food production,” Segantini said.

During his PhD, Segantini contacted a wide range of industries and identified olive oil producers and breweries as pilot customers. Until now, these companies have tested their products using elaborate chemical methods, which can produce toxic waste.

“EPRoC is not only much more sensitive, it is also less time-consuming, so samples can be analysed repeatedly throughout the process. This provides additional insights that can be used to optimise production processes to extend the shelf life and oxidative resistance of the products,” Segantini said.

In the future, the founders plan to adapt their product to other areas of application, such as medical diagnostics, drug development, semiconductor technology and battery monitoring.

Call for comment on endo-1,4-beta-xylanase as a processing aid

Food Standards Australia New Zealand (FSANZ) is calling for comment on an application to permit...

UV light technology to curb viral transmission in poultry environments

Widespread bird flu outbreaks underscore the urgent need for disinfection solutions to curb viral...

Aussie Barramundi farm achieves certification for responsible aquaculture

Northern Territory's Humpty Doo Barramundi is claimed to be the first Australian Barramundi...