Particle size analysis of chocolate powder

Chocolate is actually a mix of powders, which first gets liquefied, then hardened and finally moulded during the production process. The process is complex and needs to be optimised with regards to the high costs of the raw materials.

To make chocolate, cocoa liquor is milled together with excess cocoa butter and additives, such as sugar and milk powder. Particle size affects the production process and final properties of chocolate in many ways. One of the most important economic aspects in chocolate manufacturing is its viscosity, which increases as the particles become finer. By optimising particle size distribution (PSD), the manufacturer can also reduce the proportions of viscosity modifiers needed in the chocolate, thus indirectly influencing quality.

A more direct way to influence quality is to reduce the size of sugar, milk, and cocoa particles to sizes <30 µm, as larger particles feel gritty in the mouth. The human tongue is very sensitive, and differences in particle size as small as 3 µm can consistently be detected.

In conclusion, a narrow PSD is desirable to preserve the smoothness of the texture and taste from the negative influence of larger particles, and to prevent the smallest particles from impairing the flow properties. Since controlling the PSD will allow the manufacturer to both increase quality and reduce production costs, a reliable method for particle size analysis of chocolate powder is crucial.

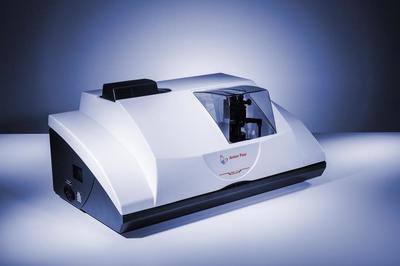

The Particle Size Analyser PSA 1190 from Anton Paar is able to perform measurements on sugar, milk powder and chocolate powder — including much bulkier agglomerated chocolate powder used in the preparation of instant hot chocolate. Dry Jet Dispersion technology ensured adequate sample dispersion under low air pressure, which is especially important for the fragile chocolate powders.

Six beverage trends predicted for 2026

Demand for customisation, 'protein-ification' and sustainable storytelling are some of...

Making UHT processing less intensive on energy

A nutritional beverages company was seeking a more sustainable way to produce UHT beverages using...

Tasty twist for chocolate alternatives

Food scientists develop two novel flavour-boosting techniques to transform carob pulp into a...