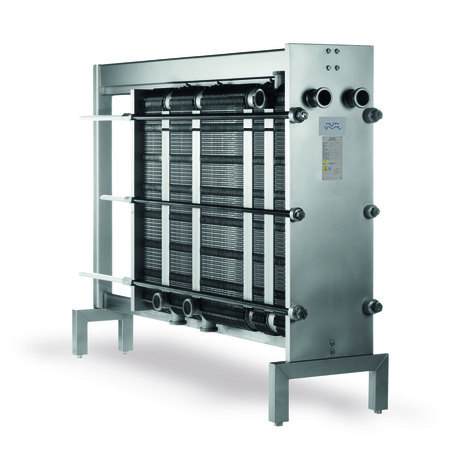

How to reduce gasketed plate heat exchanger downtime

Getting the best plate heat exchanger performance requires preventive maintenance, especially for hygienic applications within the food, dairy, beverage and pharmaceutical industries.

Each process system, however, is different with different parameters that affect the heat transfer and sealing efficiencies of the plates and gaskets.

The material properties and construction of gaskets should be specifically selected to provide optimal sealing performance for the intended application. But over time, all gaskets will wear due to natural ageing as well as the temperature, pressure and stress of normal operating conditions.

Knowing exactly when to replace gaskets is almost impossible since the timing varies, depending on the application, but you can be assured that without preventive maintenance, you risk unplanned downtime that can be costly.

Things to consider:

- Temperature and pressure: Higher operating temperatures and pressure cause more wear and tear on the gaskets.

- Compression: Gaskets are subjected to local stress from the moment you first clip them on to and tighten the plates.

- Store spare gaskets in a sealed bag, in a dry, cold and dark place, and away from ozone-producing equipment such as machines or light armatures.

Heat exchanger solutions for 5 challenging foodstuffs

In this article, five of the most challenging foodstuffs in terms of thermal processing are...

Optical tech sorts out the frozen veggies at Twin City Foods

The US frozen vegetable processor has partnered with Key Technology to install two optical...

Integrated technology for wastewater solution at beverage company

Rockwell Automation has provided integrated technology for PFi's wastewater treatment...