Colour-change sensor to detect packaged food spoilage

Food quality monitoring throughout the supply chain is critical to ensure global food safety and minimise food loss.

Massachusetts Institute of Technology (MIT) engineers have designed a ‘Velcro-like’ food sensor, made from an array of silk microneedles, that pierces through plastic packaging to sample food for signs of spoilage and bacterial contamination.

Once the design is optimised, the sensor could be used at various stages along the supply chain, from operators in processing plants, who can use the sensors to monitor products before they are shipped out, to consumers.

The sensor’s microneedles are moulded from a solution of edible proteins found in silk cocoons, and are designed to draw fluid into the back of the sensor, which is printed with two types of specialised ink. One of these ‘bio-inks’ changes colour when in contact with fluid of a certain pH range, indicating that the food has spoiled; the other turns colour when it senses contaminating bacteria such as pathogenic E. coli.

“Silk is completely edible, nontoxic and can be used as a food ingredient, and it’s mechanically robust enough to penetrate through a large spectrum of tissue types, like meat, peaches and lettuce,” said Benedetto Marelli, the Paul M. Cook Career Development Assistant Professor in MIT’s Department of Civil and Environmental Engineering.

The researchers attached the sensor to a fillet of raw fish that they had injected with a solution contaminated with E. coli. After less than a day, they found that the part of the sensor that was printed with bacteria-sensing bio-ink turned from blue to red — a clear sign that the fish was contaminated. After a few more hours, the pH-sensitive bio-ink also changed colour, signalling that the fish had also spoiled.

The results, published in the journal Advanced Functional Materials, are a first step towards developing a new colorimetric sensor that can detect signs of food spoilage and contamination.

Marelli’s co-authors on the paper are Doyoon Kim, Yunteng Cao, Dhanushkodi Mariappan, Michael S Bono Jr and A John Hart.

The new food sensor is the product of a collaboration between Marelli, whose lab harnesses the properties of silk to develop new technologies, and Hart, whose group develops new manufacturing processes.

Testing a deeper detection

To make the new sensor, Kim first made a solution of silk fibroin, a protein extracted from moth cocoons, and poured the solution into a silicone microneedle mould. After drying, he peeled away the resulting array of microneedles, each measuring about 1.6 millimetres long and 600 microns wide — about one-third the diameter of a spaghetti strand.

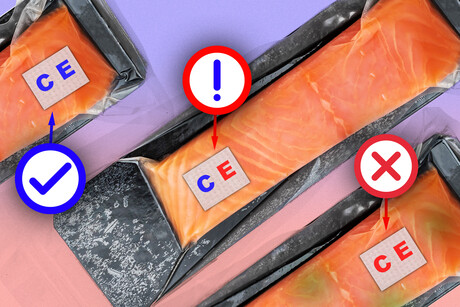

The researchers made a bio-ink containing antibodies sensitive to E. coli and a second bio-ink sensitive to pH levels that are associated with spoilage. They printed the bacteria-sensing bioink on the surface of the microneedle array, in the pattern of the letter “E”, next to which they printed the pH-sensitive bioink, as a “C”. Both letters initially appeared blue in colour.

Kim then embedded pores within each microneedle to increase the array’s ability to draw up fluid via capillary action. To test the new sensor, he bought several fillets of raw fish from a local grocery store and injected each fillet with a fluid containing either E. coli, Salmonella or the fluid without any contaminants. He stuck a sensor into each fillet. Then, he waited.

After about 16 hours, the team observed that the “E” turned from blue to red, only in the fillet contaminated with E. coli, indicating that the sensor accurately detected the bacterial antigens. After several more hours, both the “C” and “E” in all samples turned red, indicating that every fillet had spoiled.

The researchers also found their new sensor indicates contamination and spoilage faster than existing sensors that only detect pathogens on the surface of foods.

“There are many cavities and holes in food where pathogens are embedded, and surface sensors cannot detect these,” Kim said. “So we have to plug in a bit deeper to improve the reliability of the detection. Using this piercing technique, we also don’t have to open a package to inspect food quality.”

The team is now looking for ways to speed up the microneedles’ absorption of fluid, as well as the bio-inks’ sensing of contaminants.

Six beverage trends predicted for 2026

Demand for customisation, 'protein-ification' and sustainable storytelling are some of...

Making UHT processing less intensive on energy

A nutritional beverages company was seeking a more sustainable way to produce UHT beverages using...

Tasty twist for chocolate alternatives

Food scientists develop two novel flavour-boosting techniques to transform carob pulp into a...