Flow wrap packaging applications webinar from Mettler-Toledo

Mettler-Toledo Product Inspection’s webinar titled ‘4 Steps to Maximise Product Quality in Horizontal Flow Wrap Applications’ is scheduled for Wednesday, 8 May, with sessions at 9:00 am and 3:00 pm GMT.

Attendees will hear from industry experts as they explore the challenges confronting food manufacturers packaging products in flow wraps. Against the backdrop of evolving packaging regulations, manufacturers grapple with intricate challenges, including packaging complexities and accelerated production, all of which can diminish crucial manufacturing time and accuracy. This webinar will explore strategies for navigating these constraints to combat rising manufacturing costs and enhance production efficiency.

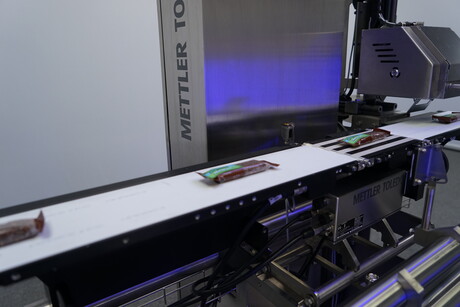

Experts on the webinar will discuss four key steps to optimise product quality in packaging. These steps include advanced inspection technologies such as metal detection, X-ray, vision technology and checkweighing, specifically tailored to address the unique requirements of horizontal flow-wrapped production lines for high-speed applications, such as snacks.

Presenting this webinar is Niall McRory, the Global Key Account Manager at Mettler-Toledo, who has over 24 years’ experience and expertise in food safety.

“We understand the critical importance of maintaining product quality and safety in flow wrap applications, especially in the fast-paced snack industry,” McRory said. “Our webinar aims to provide practical strategies and demonstrations to help manufacturers maximise efficiency and compliance in their production processes.”

The program’s main focal points include:

Production principles and manufacturer needs:

Understanding the fundamental principles guiding production processes and the specific needs of manufacturers in the industry.

Product inspection application along the horizontal flow wrap line:

Exploring the application of product inspection technologies throughout the horizontal flow wrap line to facilitate comprehensive quality control.

Inspection of raw product:

Examining the importance of inspecting raw products before they enter the packaging process to detect any contaminants or irregularities and save packaging material costs.

Inspection after primary packaging:

Highlighting the significance of inspecting products after primary packaging to verify packaging integrity and offer high product quality.

Inspection after secondary packaging:

Discussing the necessity of inspecting products after secondary packaging for bulk goods to address any potential issues introduced during this stage.

Data management and service offering:

Exploring the role of data management solutions such as PRODX in overseeing product inspection processes and the importance of service offerings in ensuring equipment reliability and performance.

To find out more or to register for the webinar, visit www.mt.com/pi-flowwrap-webinar-pr.

Matthews' stand offering deep 2D barcoding intel at FoodTech Qld

2D barcode demonstrations will be part of Matthews' offerings on its stand at FoodTech Qld in...

Out of the box: 2025 PIDA Awards finalists announced

Finalists have been announced for the 2025 Australasian Packaging Innovation & Design (PIDA)...

Registrations open for Australasian Packaging Conference

Early-bird registrations are now open for the 2025 Australasian Packaging Conference, coordinated...