Extending the shelf life of fresh fruit and vegetables through customised packaging

Currently, refrigerators don’t automatically convert any rotting fruit and vegetables in them into biofuel which is then used to power the refrigeration system.

Up to $10 billion worth of food is wasted in Australia each year — and the food service/ready meal sector is a contributor to this.

But judicious use of intelligent packaging systems can reduce this figure — and the technology is proven and in use across Europe and in Marks & Spencer (M&S).

In order to extend the shelf life of fresh fruit and vegetables, M&S researched packaging systems that could retain the ‘freshness’ of fruit and vegetables for longer.

The best system the company found and implemented was ‘appropriate modified atmosphere packaging’ (AMAP) supplied by Dutch company PerfoTec.

With PerfoTec’s AMAP technology, all fresh produce is assessed for its respiration rate prior to packing, as respiration rates can vary from season to season and product to product. The product can then be exposed to the right amount of oxygen for sustainability, as too much oxygen causes rapid deterioration and too little causes an anaerobic environment leading to rapid decay. This atmospheric control is maintained through breathing holes in the produce packaging film.

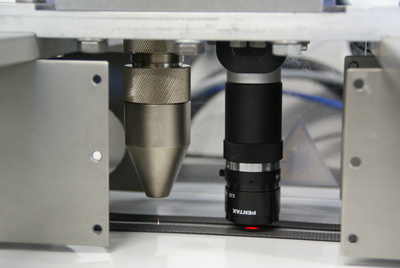

The PerfoTec system uses a laser to make miniscule perforations in the packaging film. The acquired respiration data is passed to the laser system integrated onto the packing unit and, as film passes through, predetermined breathing holes are made and then inspected by a camera for consistency. The perforations are customised to suit each fruit type to prolong freshness.

Using this PerfoTec system has enabled M&S to extend the life of grapes by 5–7 days, raspberries by 5–10 days and strawberries by 4–8 days. As extra benefits the company has reduced food waste, increased profits and enhanced consumer perceptions. M&S will not accept some lines of fresh fruit unless it has been packaged using the PerfoTec system.

Why aren’t we packaging our fruits and vegetables like this in Australia and New Zealand?

The local supermarkets insist that Australians prefer to self-select from open bins and that consumers believe that pre-packed fruit and vegetables are seconds, poor quality, old stock or no longer fresh. This perception is reinforced when packaging is used to move slow-selling or tired-looking items — for example, celery and rhubarb are cut into lengths and wrapped ‘ready to go’, or pumpkin cut and wrapped into ‘smaller portions’. However, fresh produce purchases could retain quality, taste and smell, and last longer in the refrigerator, if they were packaged with the life of the product in mind.

Innovation is the key to change. By keeping fresh produce fresh, giving it a longer shelf life will not only increase benefits for local consumers but our overseas markets as well.

Phone: 02 9979 7646

KRAIBURG TPE FC/CM3/AD1 compound series

The KRAIBURG TPE FC/CM3/AD1 compound series with adhesion to polar thermoplastics is designed for...

Sidel EvoBLOW Laser

Sidel introduced the EvoBLOW Laser to the Middle East at Gulfood Manufacturing 2025.

Packserv four-head, 5 L pneumatic filling machine

The pneumatic filling machine is suitable for food, pharmaceutical, HACCP and TGA-compliant...